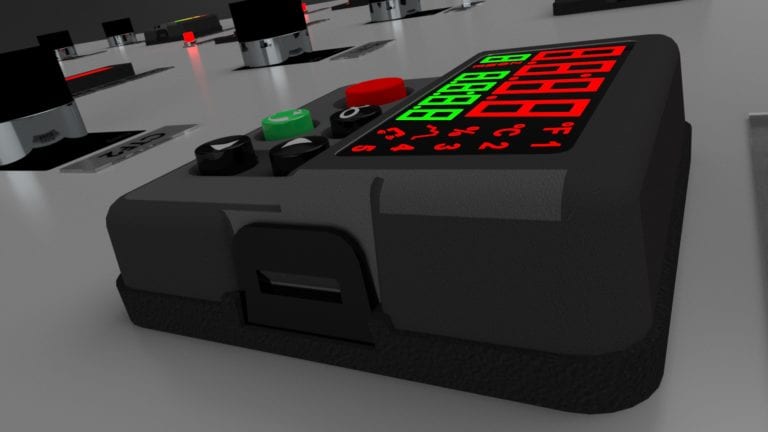

Control Panels for Chillers: Process Temperature Packages

Engineering

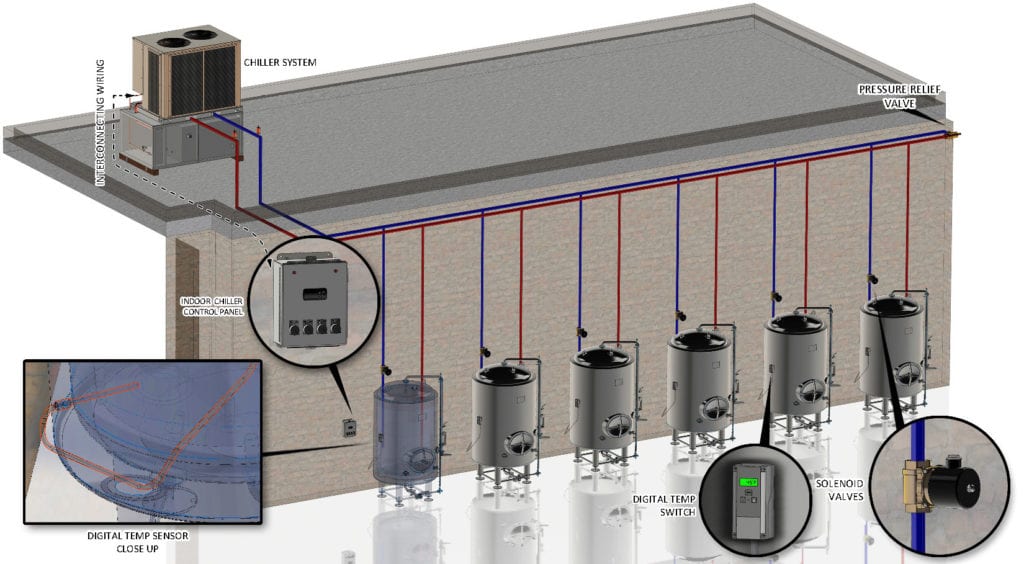

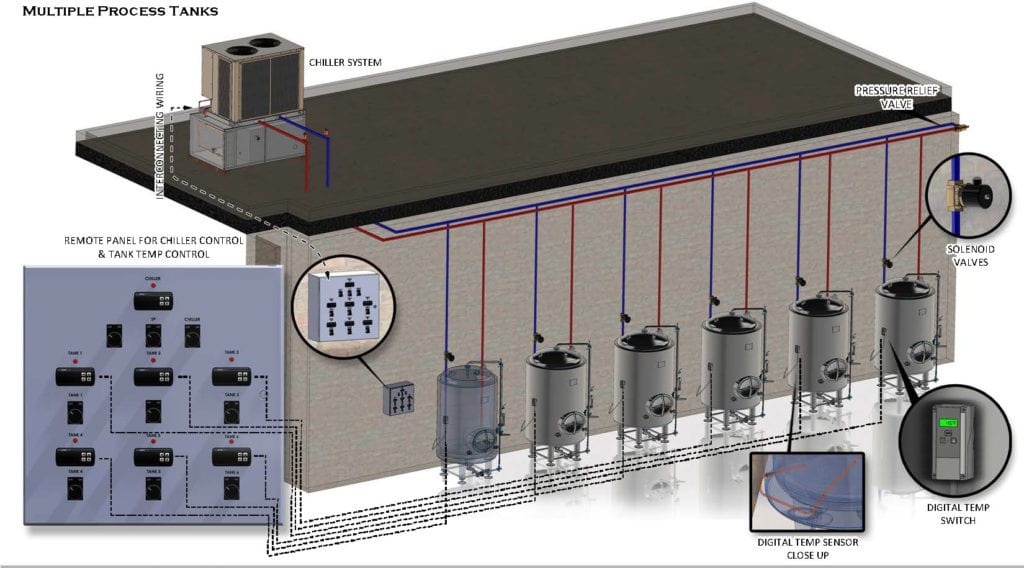

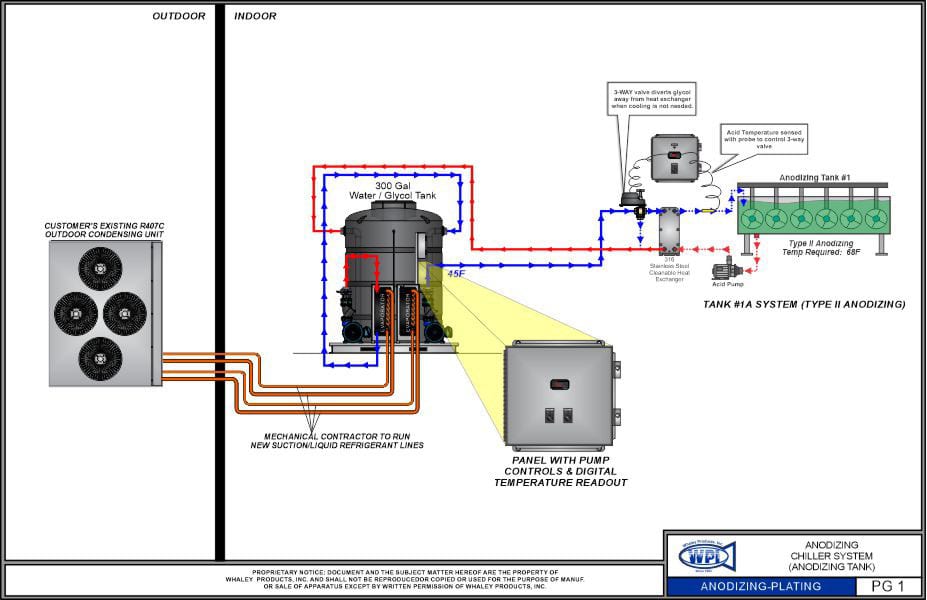

Our engineering team makes sure your custom chiller design is thoroughly analyzed and rendered for your approval so that you can see all your industrial cooling equipment with tanks, pumps, evaporator, etc. and its configuration before it’s produced.

Design

Every installation site is unique, so your cooling system design should be, too. We don’t try to squeeze you into a “one size fits all” chiller package – our sales engineers ask the right questions, do the calculations, and make sure your cooling design is done right the first time.

Quality

Whaley Products, Inc. knows that manufacturing quality air-cooled, water-cooled and cooling tower equipment along with providing excellent service right here in the USA is the best way to take care of our customers. Only systems that pass the WHALE-SOFT™ test environment are securely crated and shipped out.