Closed Loop Cooling Tower and Heat Transfer Pump Tank Skid 07

Complete Closed Loop Cooling Tower System 07

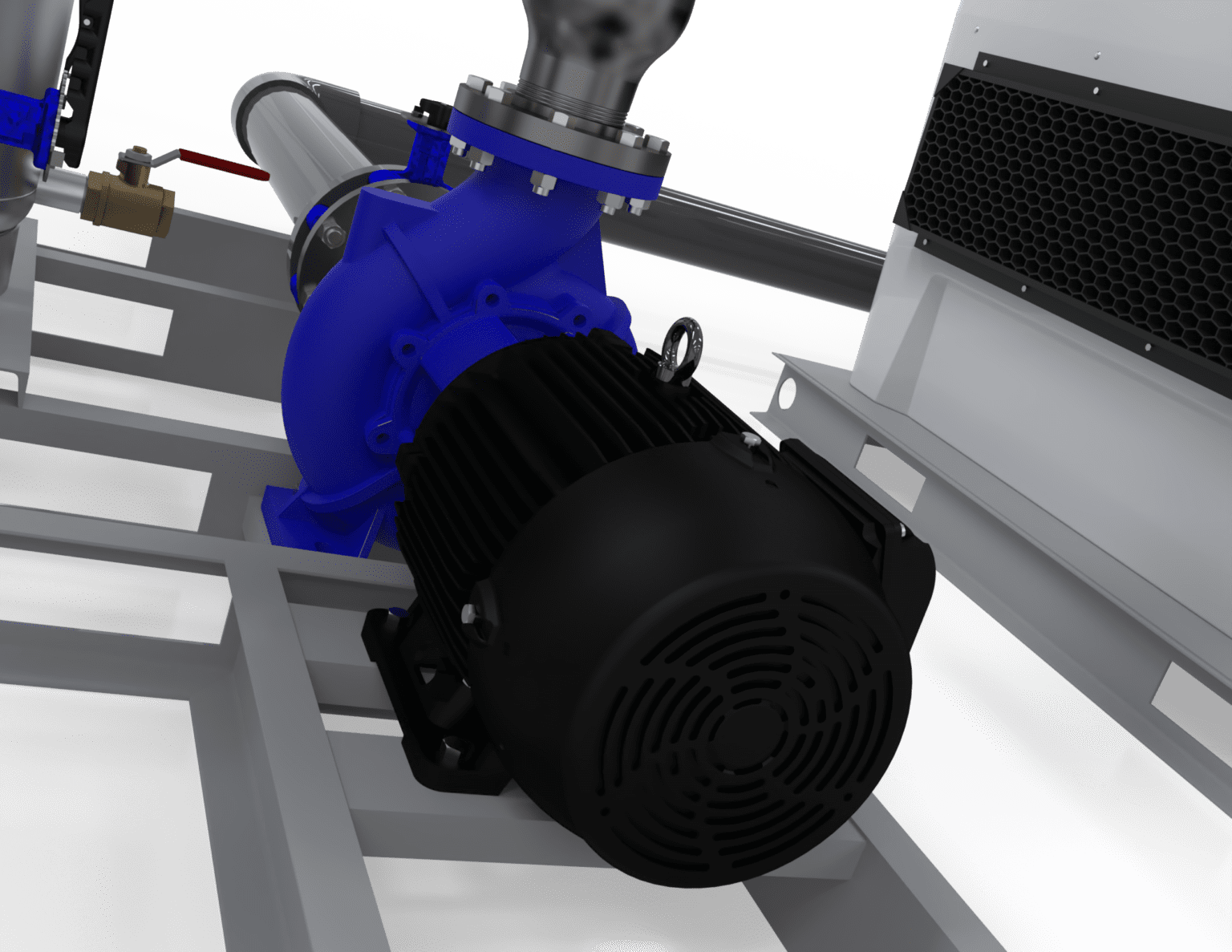

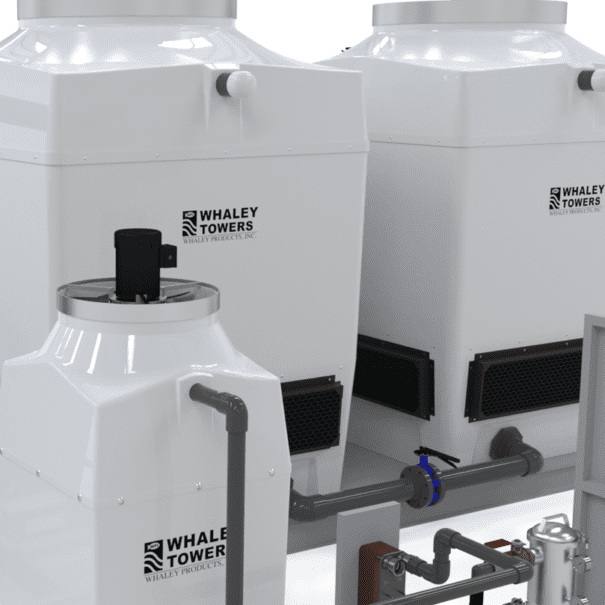

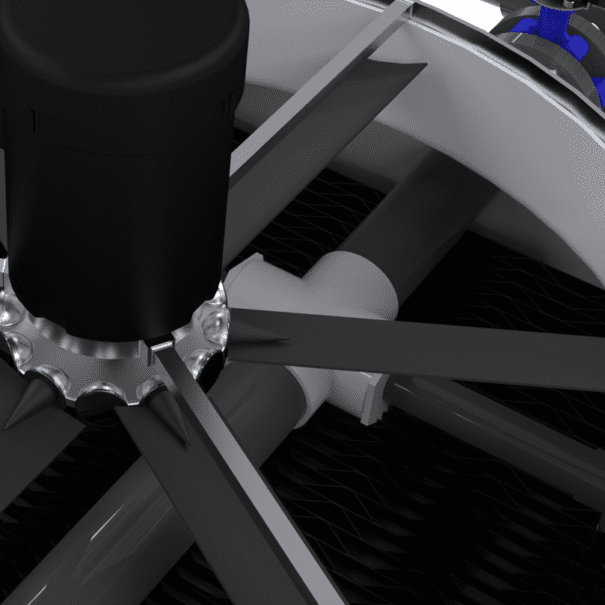

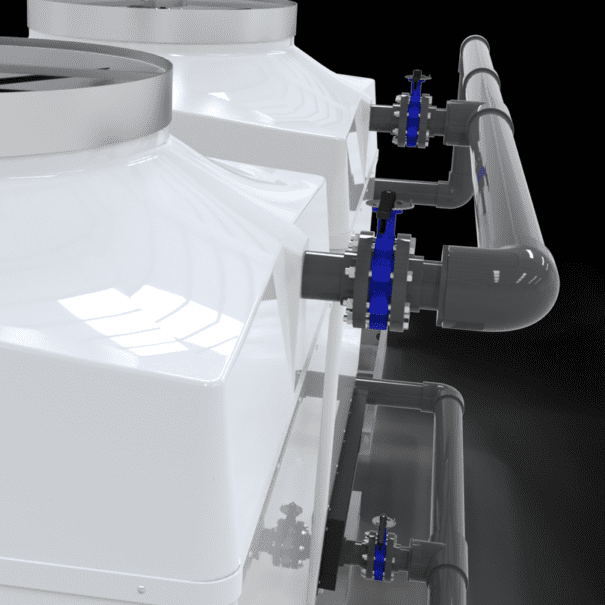

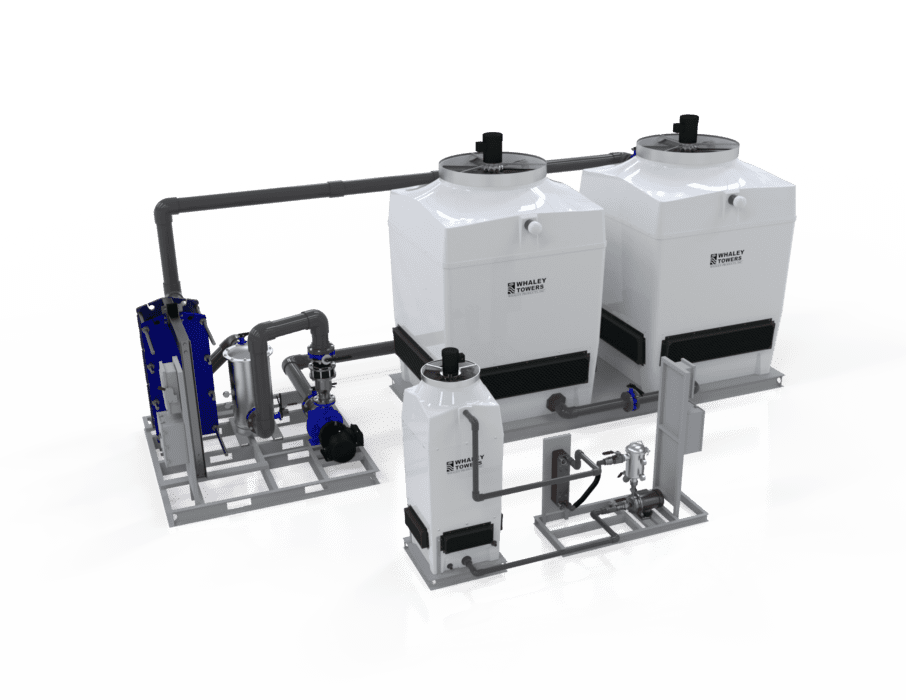

The WP-Series System 07 manufactured by Whaley Products, Inc. is a complete closed loop cooling tower system used to isolate tower fluid from process fluid. This configuration can serve applications in ranges from 10 to 750 tons. With closed loop towers, the tower water is isolated from the process fluid, therefore allowing you to utilize this system to cool other fluids including glycol, salt water, oil, among others. It also helps maintain a clean process fluid. This configuration includes an open loop tower(s) in conjunction with a separate skidded heat transfer pump skid. Included on this skid is an isolation heat exchanger, strainer, cooling tower circulation pump, disconnect panel and controls. The isolation heat exchanger is specifically chosen for the client’s fluid, flow rate, and temperatures. Included in the controls are on/off switches for the pump and tower fan(s). It also includes a digital temperature controller that cycles the tower fan based on tower basin temperature. This configuration is helpful for customers who want to isolate the process fluid from the tower in instances of high temperatures and process fluids other than water. This configuration is great for scenarios where dimensional constraints exist in the area near the cooling tower installation. It is also best suited where all equipment can be installed outdoors on a concrete pad or roof and do not need process side equipment.

Closed Loop Cooling Tower and Heat Transfer Pump Tank Skid 07

This complete closed loop cooling tower system is made up of an Evaporative Induced Draft Cooling Tower Module and a Pump Station Heat Transfer Skid. The cooling tower module is factory mounted on an epoxy coated steel frame with fork slots and lifting eyes. The Pump Station Heat Transfer Skid includes a cooling tower/heat exchanger circulation pump that will pull from the tower’s lower water basin, circulate the plate and frame heat exchanger, and return to the cooling tower. Additionally, a full flow flushable stainless-steel strainer is included to strain the cooling tower water prior to going through the plate and frame heat exchanger. Also included are the controls to run the pump and tower fan.

Available Closed Loop Cooling Tower and Heat Transfer Pump Tank Skid 07 Models

Use this chart to browse our Closed Loop Cooling Tower and Heat Transfer Pump Tank Skid 07 models. Unit capacities have been illustrated at various hypothetical site conditions.

Our Sales Engineers are available to assist in choosing the right system for your application and answer any questions you may have.

* Performance Illustrated at Hypothetical Conditions of 95F Ambient, 50% Propylene Glycol, Up to 2000 Feet Elevation, 60Hz Power.

** Performance Illustrated at Standard Site Conditions of 95F Ambient, 0% Glycol, Up to 2000 Feet Elevation, 60Hz Power.

*** Performance Illustrated at Hypothetical Conditions of 95F Ambient, 0% Propylene Glycol, Up to 2000 Feet Elevation, 60Hz Power.

Contact a Whaley sales engineer to obtain performance ratings at your specific site conditions.

| Model | Nominal Capacity (tons) | Nominal Capacity (BTU/hr) | Nominal Capacity (kW) | Air Flow (cfm) | Flow Rate (gpm) | Water Usage (gpm) | CTHXP @17.3 psi | Inlet/Outlet (in) | Control Panel | Fan Motor (HP) |

|---|---|---|---|---|---|---|---|---|---|---|

| CLS650-10-T-X-PTHXSS | 10 | 150,000 | 43.88 | 3,000 | 30 | 0.30 | 0.75 | 2 | YES | 0.50 |

| CLS650-15-T-X-PTHXSS | 15 | 225,000 | 65.81 | 3,250 | 45 | 0.45 | 1 | 2 | YES | 0.50 |

| CLS850-20-T-X-PTHXSS | 20 | 300,000 | 87.75 | 6,000 | 60 | 0.60 | 1 | 2 | YES | 0.75 |

| CLS850-25-T-X-PTHXSS | 25 | 375,000 | 109.69 | 6,500 | 75 | 0.75 | 1.5 | 2 | YES | 0.75 |

| CLS1250-30-T-X-PTHXSS | 30 | 450,000 | 131.63 | 11,300 | 90 | 0.90 | 2 | 2 | YES | 2 |

| CLS1250-40-T-X-PTHXSS | 40 | 600,000 | 175.50 | 12,000 | 120 | 1.20 | 2 | 3 | YES | 2 |

| CLS1550-50-T-X-PTHXSS | 50 | 750,000 | 219.38 | 15,000 | 150 | 1.50 | 2 | 3 | YES | 3 |

| CLS1550-60-T-X-PTHXSS | 60 | 900,000 | 263.25 | 16,250 | 180 | 1.80 | 3 | 3 | YES | 3 |

| CLS1550-75-T-X-PTHXSS | 75 | 1,125,000 | 329.06 | 17,500 | 225 | 2.25 | 3 | 3 | YES | 3 |

| CLS1850-100-T-X-PTHXSS | 100 | 1,500,000 | 438.75 | 20,500 | 300 | 3.00 | 5 | 3 | YES | 5 |

| CLS1850-125-T-X-PTHXSS | 125 | 1,875,000 | 548.40 | 22,700 | 375 | 3.75 | 7.5 | 3 | YES | 5 |

| CLS2-1550-150-T-X-PTHXSS | 150 | 2,250,000 | 658.13 | 35,000 | 450 | 4.50 | 7.5 | 3 | YES | 2ea 3 |

| CLS2-1850-200-T-X-PTHXSS | 200 | 3,000,000 | 877.50 | 41,000 | 600 | 6.00 | 10 | 4 | YES | 2ea 5 |

| CLS2-1850-250-T-X-PTHXSS | 250 | 3,750,000 | 1,096.88 | 45,400 | 750 | 7.50 | 10 | 6 | YES | 2ea 5 |

| CLS3-1850-300-T-X-PTHXSS | 300 | 4,500,000 | 1,316.25 | 61,500 | 900 | 9.00 | 15 | 6 | YES | 3ea 5 |

| CLS3-1850-375-T-X-PTHXSS5 | 375 | 5,625,000 | 1,645.30 | 68,100 | 1,125 | 11.25 | 15 | 4 | YES | 3ea 5 |

| CLS4-1850-400-T-X-PTHXSS | 400 | 6,000,000 | 1,755.00 | 82,000 | 1,200 | 12.00 | 20 | 6 | YES | 4ea 5 |

| CLS4-1850-500-T-X-PTHXSS | 500 | 7,500,000 | 2,193.75 | 90,800 | 1,500 | 15.00 | 25 | 6 | YES | 4ea 5 |

| CLS5-1850-625-T-X-PTHXSS | 625 | 9,375,000 | 2,742.19 | 113,500 | 1,875 | 18.75 | 30 | 6 | YES | 5ea 5 |

| CLS6-1850-750-T-X-PTHXSS | 750 | 11,250,000 | 3,290.63 | 136,200 | 2,250 | 22.50 | 30 | 6 | YES | 6ea 5 |

Standard Features

Options

Controllers

Thermal Wells

Strainers & Filtration

Variable Frequency Drives

Basin Heaters

Electrical Disconnects

Extra Fittings

Tanks

Pumps

Elevation Packages

Contact Us Today!

Have a question? Need a quote? Sales Engineers are standing by to help.

Simply fill out our form, or give us a call at 940-569-4116.

At Whaley Products, Inc. we manufacture quality industrial cooling systems for a wide range of processes and applications. A commitment to precision engineering and innovative design have made Whaley Chillers the choice of Industry Leaders.