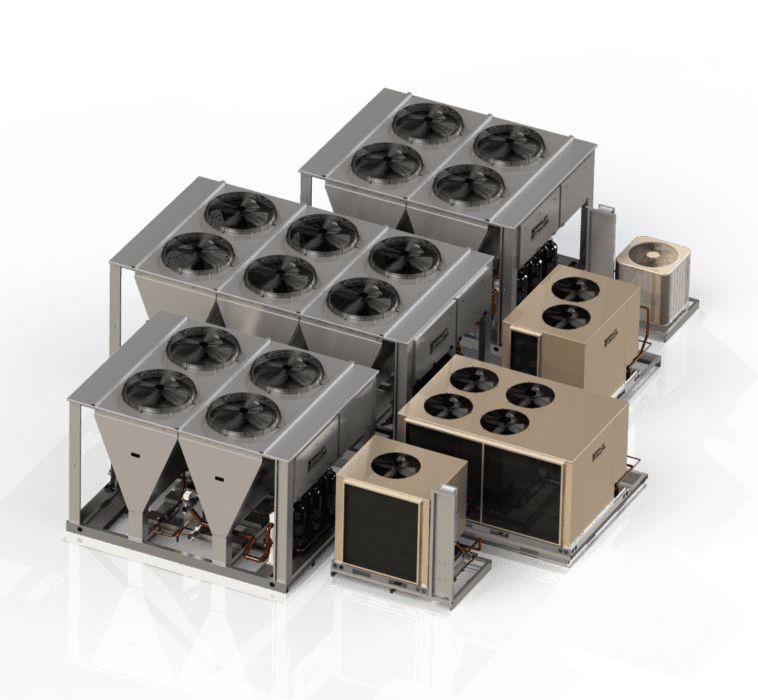

Modular Air-Cooled Chillers

Modular Air-Cooled Chillers, the SAE-Series manufactured by Whaley Products, Inc., is a redundant chiller unit for high redundancy needs. Frequently multiple SAE-Series units are selected in conjunction with a C-Series pump tank system to provide high redundancy for critical heat load applications. The SAE-Series systems are typically purchased initially with a single chiller module with a pump tank to start with. With the initial setup, WPI can size the pump tank system for unlimited capacity. One of the benefits of the SAE-Series is its redundancy. By using multiple modules, it gives the high redundancy you need for critical heat load applications that cannot have any downtime. This system can be used for any heat load applications due to having no restrictions on capacity. The pump tank system’s reservoir can be sized for whatever your desired volume is which gives you more temperature stability as well as the ability to “store btu/hr” to help minimize chiller size. The SAE-Series coupled with the C-Series Pump Tank System also allows for multiple configurations and flexible design. WPI can provide but are not limited to redundant pumps, variable frequency drives, different tank materials, different plumbing materials (including those for food applications), and many more.

Modular Air-Cooled Chillers

The SAE-Series is a modular chiller system. This includes an air-cooled condensing unit coupled with an evaporator(s). It does not include a tank or pumps, so a tank and pumps will need to be supplied in conjunction with this system. WPI can provide these heat transfer skids to work along side with these units if needed.

Available Models

Use this chart to browse our modular air-cooled chillers. SAE-Series Unit capacities have been illustrated at various hypothetical site conditions. Our Sales Engineers are available to assist in choosing the right system for your application and answer any questions you may have. * Performance Illustrated at Hypothetical Conditions of 95F Ambient, 50% Propylene Glycol, Up to 2000 Feet Elevation, 60Hz Power. ** Performance Illustrated at Standard Site Conditions of 95F Ambient, 0% Glycol, Up to 2000 Feet Elevation, 60Hz Power. *** Performance Illustrated at Hypothetical Conditions of 95F Ambient, 0% Propylene Glycol, Up to 2000 Feet Elevation, 60Hz Power. Contact a Whaley sales engineer to obtain performance ratings at your specific site conditions.

| Base Model | Nominal Capacity (tons) | Nominal Capacity (kW) | *Capacity (BTU/hr) Illustrated @ 25F/-3.9C | **Capacity (BTU/hr) Illustrated @ 50F/10C | ***Capacity (BTU/hr) Illustrated @ 65F/18.3C | Refrigerant Circuits | Required Flow Rate (gpm) | Inlet/Outlet FNPT (in) | Length (in) | Width (in) | Height (in) | Shipping Weight (lbs) | Operational Weight (lbs) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SAE1.5 | 1.5 | 5.27 | 8,856 | 18,000 | 22,428 | 1 | 3.6 | 1 | 42 | 36 | 60 | 400 | 400 |

| SAE2 | 2 | 7.02 | 11,808 | 24,000 | 29,904 | 1 | 4.8 | 1 | 42 | 36 | 60 | 400 | 400 |

| SAE3 | 3 | 10.53 | 17,712 | 36,000 | 44,856 | 1 | 7.2 | 1 | 42 | 36 | 60 | 400 | 400 |

| SAE4 | 4 | 14.04 | 23,616 | 48,000 | 59,808 | 1 | 9.6 | 1 | 42 | 36 | 60 | 450 | 450 |

| SAE5 | 5 | 17.55 | 29,520 | 60,000 | 74,760 | 1 | 12 | 1 | 48 | 40 | 60 | 450 | 450 |

| SAE6DS | 6 | 21.06 | 35,424 | 72,000 | 98,712 | 1 | 14.4 | 1 | 60 | 40 | 60 | 700 | 700 |

| SAE7.5DS | 7.5 | 26.33 | 44,280 | 90,000 | 112,140 | 1 | 18 | 1 | 60 | 40 | 60 | 700 | 700 |

| SAE10DS | 10 | 35.10 | 59,040 | 120,000 | 149,520 | 1 | 24 | 1 | 72 | 44 | 60 | 900 | 900 |

| SAE10D | 10 | 35.10 | 59,040 | 120,000 | 149,520 | 2 | 24 | 2 | 82 | 44 | 55 | 950 | 950 |

| SAE12.5D | 12.5 | 43.88 | 73,800 | 150,000 | 186,900 | 2 | 30 | 2 | 82 | 44 | 55 | 1050 | 1050 |

| SAE12.5 | 12.5 | 43.88 | 73,800 | 150,000 | 186,900 | 1 | 30 | 1 | 60 | 58 | 68 | 1000 | 1000 |

| SAE15 | 15 | 52.65 | 88,560 | 180,000 | 224,280 | 1 | 36 | 1 | 98 | 46 | 58 | 1650 | 1650 |

| SAE20 | 20 | 70.20 | 118,080 | 240,000 | 299,040 | 1 | 48 | 1 | 98 | 68 | 57 | 1800 | 1800 |

| SAE15D | 15 | 52.65 | 88,560 | 180,000 | 224,280 | 2 | 36 | 2 | 89 | 80 | 55 | 1800 | 1800 |

| SAE20D | 20 | 70.20 | 118,080 | 240,000 | 299,040 | 2 | 48 | 2 | 89 | 80 | 55 | 1800 | 1800 |

| SAE25 | 25 | 87.75 | 147,600 | 300,000 | 373,800 | 1 | 60 | 1 | 102 | 60 | 67 | 2018 | 2018 |

| SAE30 | 30 | 105.30 | 177,120 | 360,000 | 448,560 | 1 | 72 | 1 | 102 | 60 | 67 | 2194 | 2194 |

| SAE40 | 40 | 140.40 | 236,160 | 480,000 | 598,080 | 1 | 96 | 1 | 108 | 89 | 79 | 2772 | 2772 |

| SAE50 | 50 | 175.50 | 295,200 | 600,000 | 747,600 | 1 | 120 | 1 | 108 | 89 | 79 | 2790 | 2790 |

| SAE25D | 25 | 87.75 | 147,600 | 300,000 | 373,800 | 2 | 60 | 2 | 102 | 60 | 67 | 2048 | 2048 |

| SAE30D | 30 | 105.30 | 177,120 | 360,000 | 448,560 | 2 | 72 | 2 | 102 | 60 | 79 | 2217 | 2217 |

| SAE40D | 40 | 140.40 | 236,160 | 480,000 | 598,080 | 2 | 96 | 2 | 108 | 89 | 79 | 2928 | 2928 |

| SAE50D | 50 | 175.50 | 295,200 | 600,000 | 747,600 | 2 | 120 | 2 | 108 | 89 | 79 | 2976 | 2976 |

| SAE60D | 60 | 210.60 | 354,240 | 720,000 | 897,120 | 2 | 144 | 2 | 108 | 89 | 79 | 3097 | 3097 |

| SAE70D | 70 | 245.70 | 413,280 | 840,000 | 1,046,640 | 2 | 168 | 2 | 111 | 102 | 79 | 2712 | 2712 |

| SAE80D | 80 | 280.80 | 472,320 | 960,000 | 1,196,160 | 2 | 192 | 2 | 152 | 89 | 73 | 2873 | 2873 |

| SAE90D | 90 | 315.90 | 531,360 | 1,080,000 | 1,345,680 | 2 | 216 | 2 | 152 | 89 | 73 | 3132 | 3132 |

| SAE100D | 100 | 351.00 | 590,400 | 1,200,000 | 1,495,200 | 2 | 240 | 2 | 152 | 89 | 73 | 4001 | 4001 |

| SAE115D | 115 | 403.65 | 678,960 | 1,380,000 | 1,719,480 | 2 | 276 | 2 | 192 | 89 | 79 | 3684 | 3684 |

| SAE130D | 130 | 456.30 | 767,520 | 1,560,000 | 1,943,760 | 2 | 312 | 2 | 192 | 89 | 79 | 3870 | 3870 |

Standard Features

Highly efficient coil provides excellent heat transfer and low air resistance

High Efficient R-410A Refrigerant

Copeland Scroll compressor(s)

Insulated stainless steel copper-brazed plate evaporator(s) (Cupre Nickel available)

Thermostatic expansion valve, filter drier, sight glass installed on refrigerant lines

Service ports and valves

NEMA 4 Control panel with digital temperature controller

High and low pressure safety

Single point power connection

Direct drive fan(s) made to run slower and more quiet

Vertical air discharge fans minimizes operating sound

Weather resistant fan motor made to survive in the elements

Highly efficient coil provides excellent heat transfer and low air resistance

Assembled, plumbed, and wired on industrial epoxy-coated steel frame

Complete systems fully run tested under heat load using the WHALE-SOFT™ Testing Platform

Options

Contact Us Today!

Have a question? Need a quote? Sales Engineers are standing by to help.

Simply fill out our form, or give us a call at 940-569-4116.

At Whaley Products, Inc. we manufacture quality industrial Modular Air-Cooled Chillers systems for a wide range of processes and applications. A commitment to precision engineering and innovative design have made Whaley Chillers the choice of Industry Leaders.