Ask the Industry Expert for Help.

Let our sales engineers help you imagine the perfect system for your application. We are here and ready to give you a quote for your future system

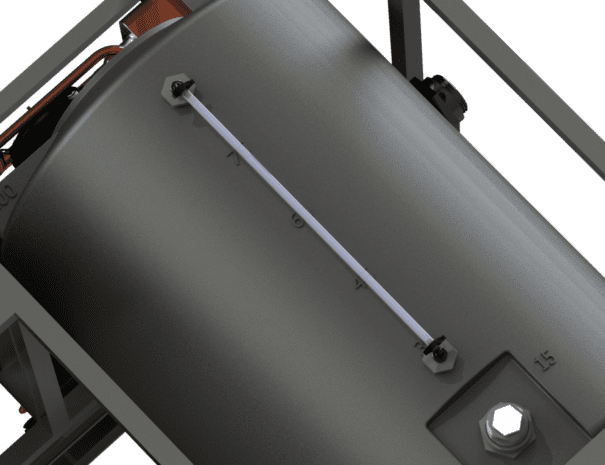

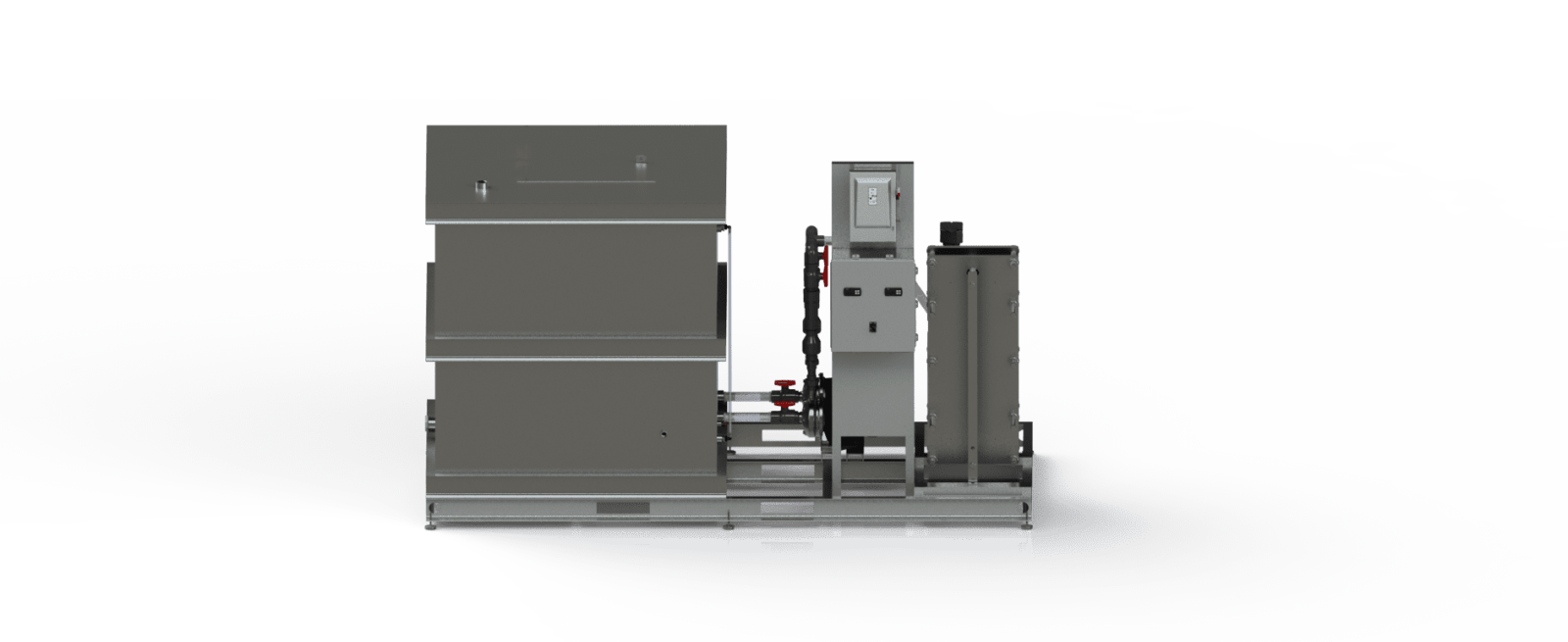

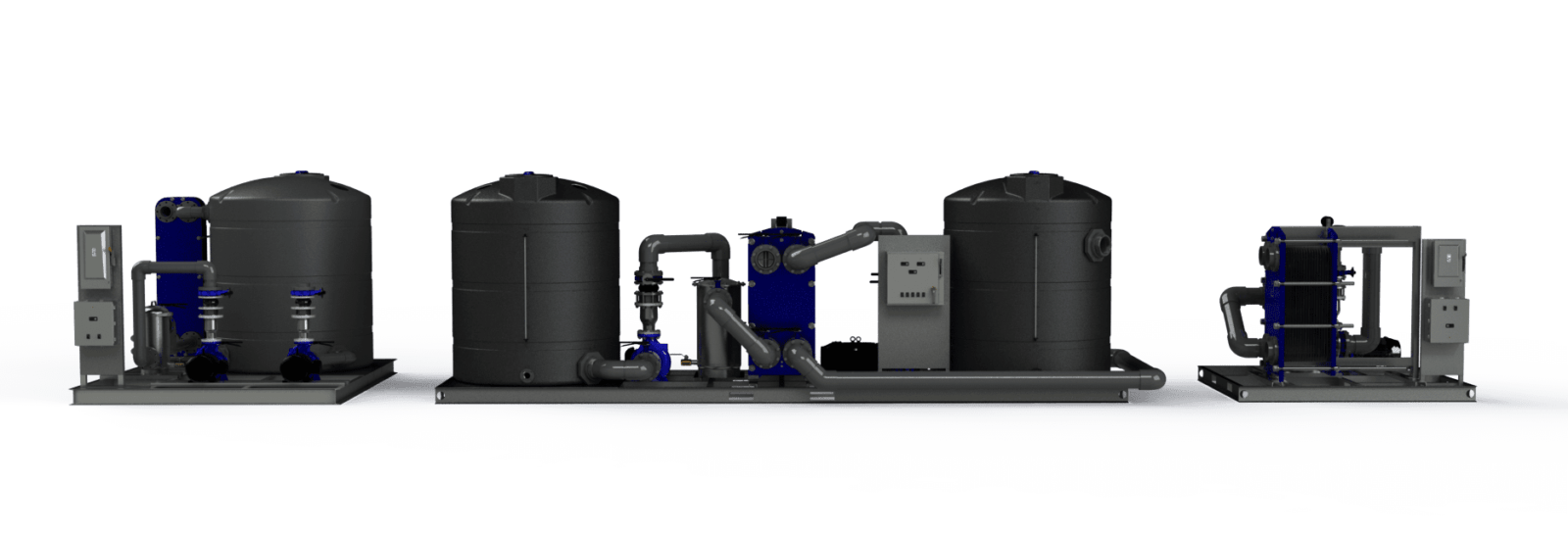

The C-Series pump tank system could quite possibly be one of Whaley's most diverse product lines. Once a tank volume is selected for a project, WPI has several options to choose from with regard to standard steel sub-frames. Larger standard sub-frames can be utilized if additional components need to be factory mounted or field mounted on the pump tank system skid. Tank materials can be high density polyethylene (HDPE), rotomolded polypropylene, fiberglass, and metallic tanks. Tank construction can be either cylindrical(round), or rectangular.

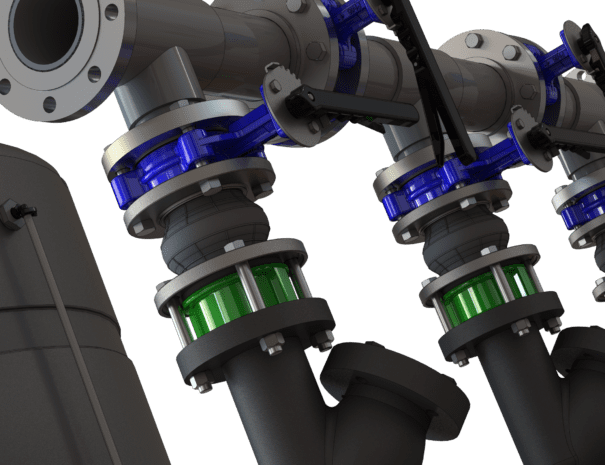

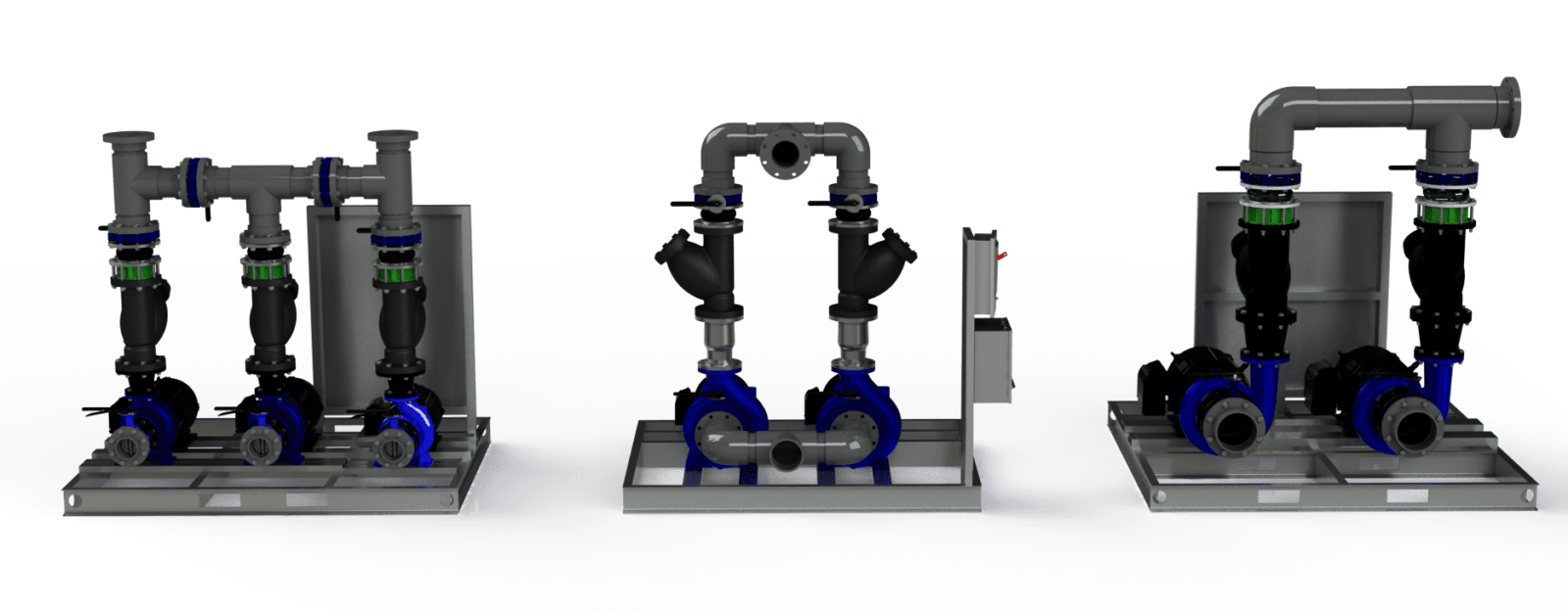

P-Series pump stations can be used to circulate process fluids through a chilled loop, cooling tower loop, heating loop, and test loops. WPI has years of experience selecting proper pumps for the most rigorous industrial installation applications. Material compatibility, temperature rating, and circulating fluid properties are some of the many factors that go into WPI's sales and engineering team selecting appropriate pumps for a project. Similar to other Whaley pump and tank systems, many customizations are available. There is virtually nothing WPI cannot do when it comes to customizing pump skids to meet application needs.

S-Series are typically used with Whaley's chiller or cooling tower systems. Stainless tank walls can be fabricated with 304, 316, 316L, or other forms of materials. A down-grade to carbon steel walls is available for applications where stainless steel is not a necessity. In these cases, water quality or other proposed tank fluid quality is addressed during the engineering phase of an S-Series pump tank system project to confirm what wall material composition is required for adequate protection against corrosion.

The T-Series pump tank system is designed to work with WPI's WP-Series FRP cooling tower systems. However, the T-Series product line is highly customizable, and can be form-fitted to work with virtually any cooling tower. In most cases, a cooling tower (WP-Series or other) is elevated either on the roof, or beside the building on sub-structural steel. The cooling tower drains to the T-Series pump tank system. This allows customers to utilize larger volume tanks to incorporate additional temperature buffer in their system design. T-Series pump tank systems can also be used in combination with Whaley's closed loop cooling tower systems as well. Additionally, WPI's cooling tower pump tanks can be designed for indoor or outdoor use. Typically insulation is not used on cooling tower pump tanks systems, but in some circumstances, insulation is utilized due to harsh outdoor site conditions.

Have a question? Need a quote? Sales Engineers are standing by to help.

Simply fill out our form, or give us a call at 940-569-4116.

At Whaley Products, Inc. we manufacture quality industrial cooling systems for a wide range of processes and applications. A commitment to precision engineering and innovative design have made Whaley Chillers the choice of Industry Leaders.

Our engineering team makes sure your custom chiller design is thoroughly analyzed and rendered for your approval so that you can see all your industrial cooling equipment with tanks, pumps, evaporator, etc. and its configuration before it’s produced.

Every installation site is unique, so your cooling system design should be, too. We don’t try to squeeze you into a “one size fits all” chiller package – our sales engineers ask the right questions, do the calculations, and make sure your cooling design is done right the first time.

Whaley Products, Inc. knows that manufacturing quality air-cooled, water-cooled and cooling tower equipment along with providing excellent service right here in the USA is the best way to take care of our customers. Only systems that pass the WHALE-SOFT™ test environment are securely crated and shipped out.

Let our sales engineers help you imagine the perfect system for your application. We are here and ready to give you a quote for your future system